The mission of the department is to produce mechanical engineers with sound engineering knowledge and skills to meet today’s aspirations and demands. The mechanical engineers have an important role to play in overcoming numerous challenges faced by our country. We are committed to providing a world-class education for the future generation of mechanical engineers who will undertake the ardent task of finding sustainable solutions to greatest engineering challenges.

Mechanical engineering is one of the oldest fields of engineering. Nevertheless, we have identified latest trends and offer a modern curricula to produce graduates with the required knowledge and skillsets.

The department offers a Bachelor of Science Honours Degree in Mechanical Engineering. We have identified that mechatronic engineering as an emerging area in recent times. All mechanical systems have integrated electronic systems for improving its performance and autonomous operation. Hence we offer a state of the art Bachelor of Science Honours Degree in Mechanical Engineering specialized in Mechatronic Engineering.

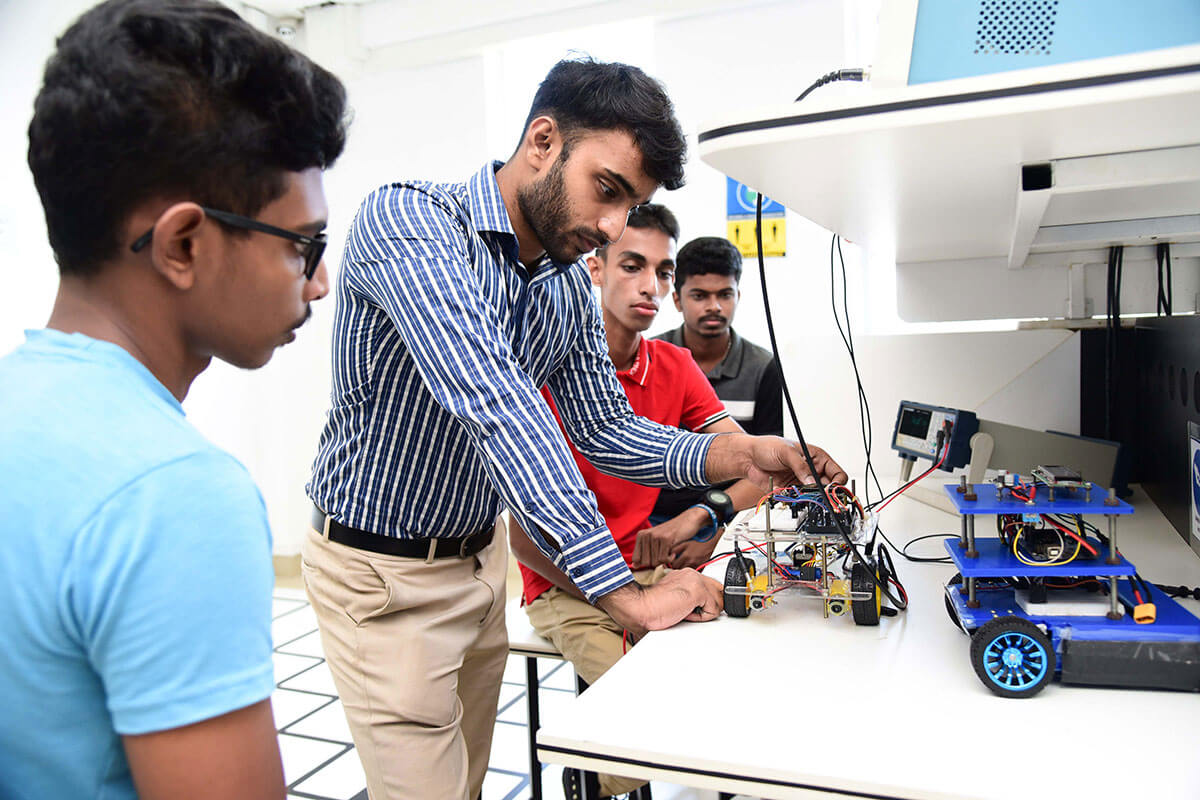

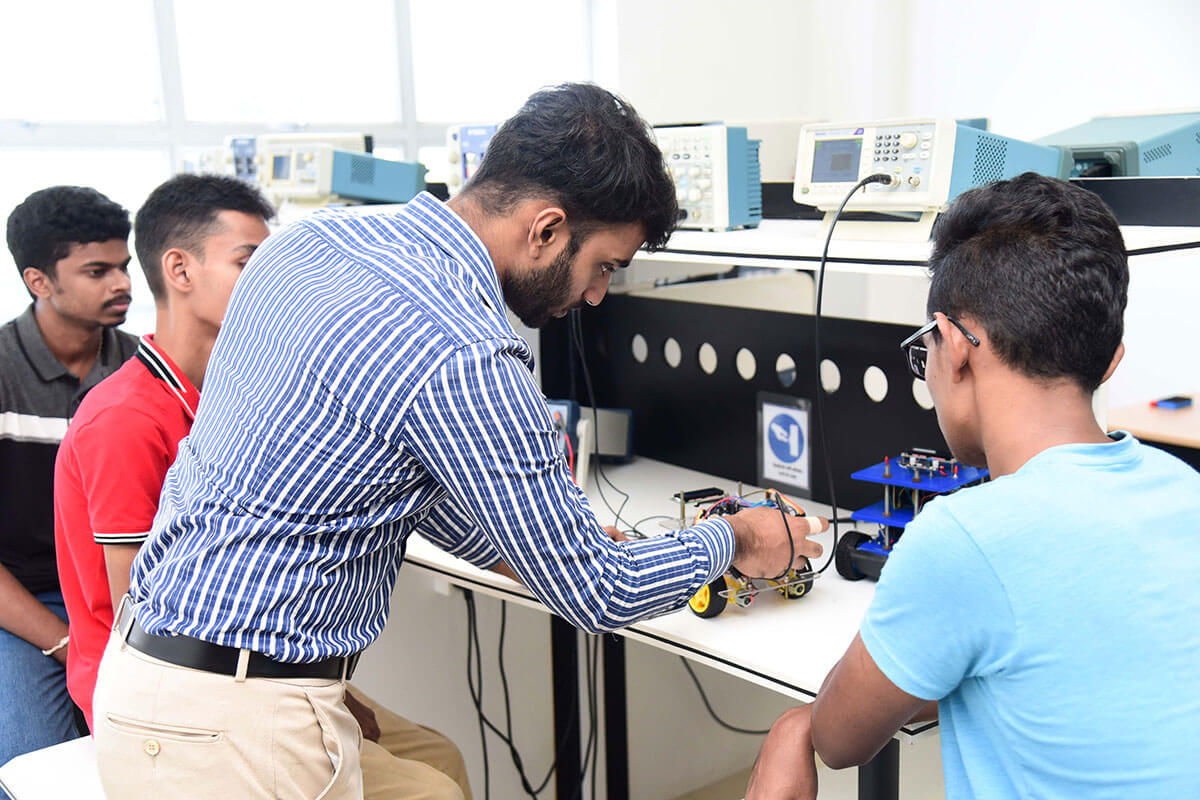

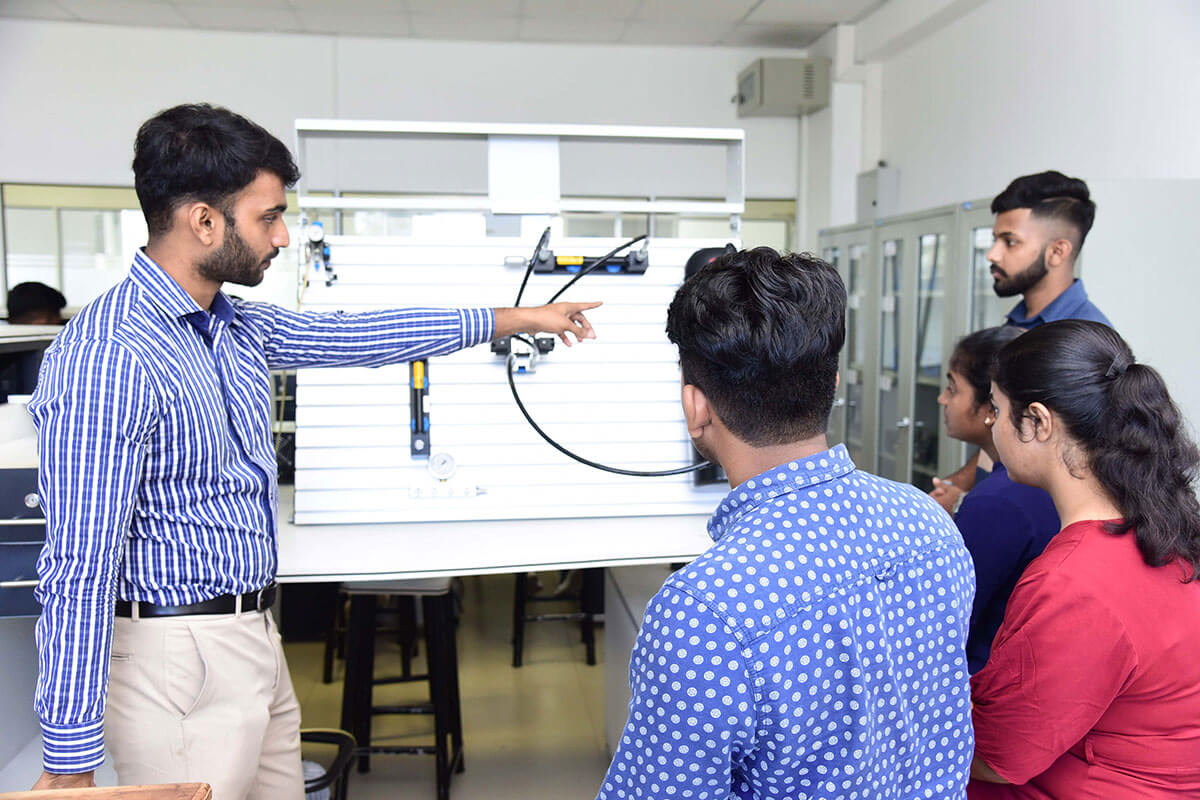

We have designed the curricula to facilitate the modern concept of student centered learning. The delivery of modules include lectures, tutorials, labs and project work. During the program, students are required to undergo a compulsory period of industrial training. The curricula meets the requirements of local and international professional and accreditation bodies.

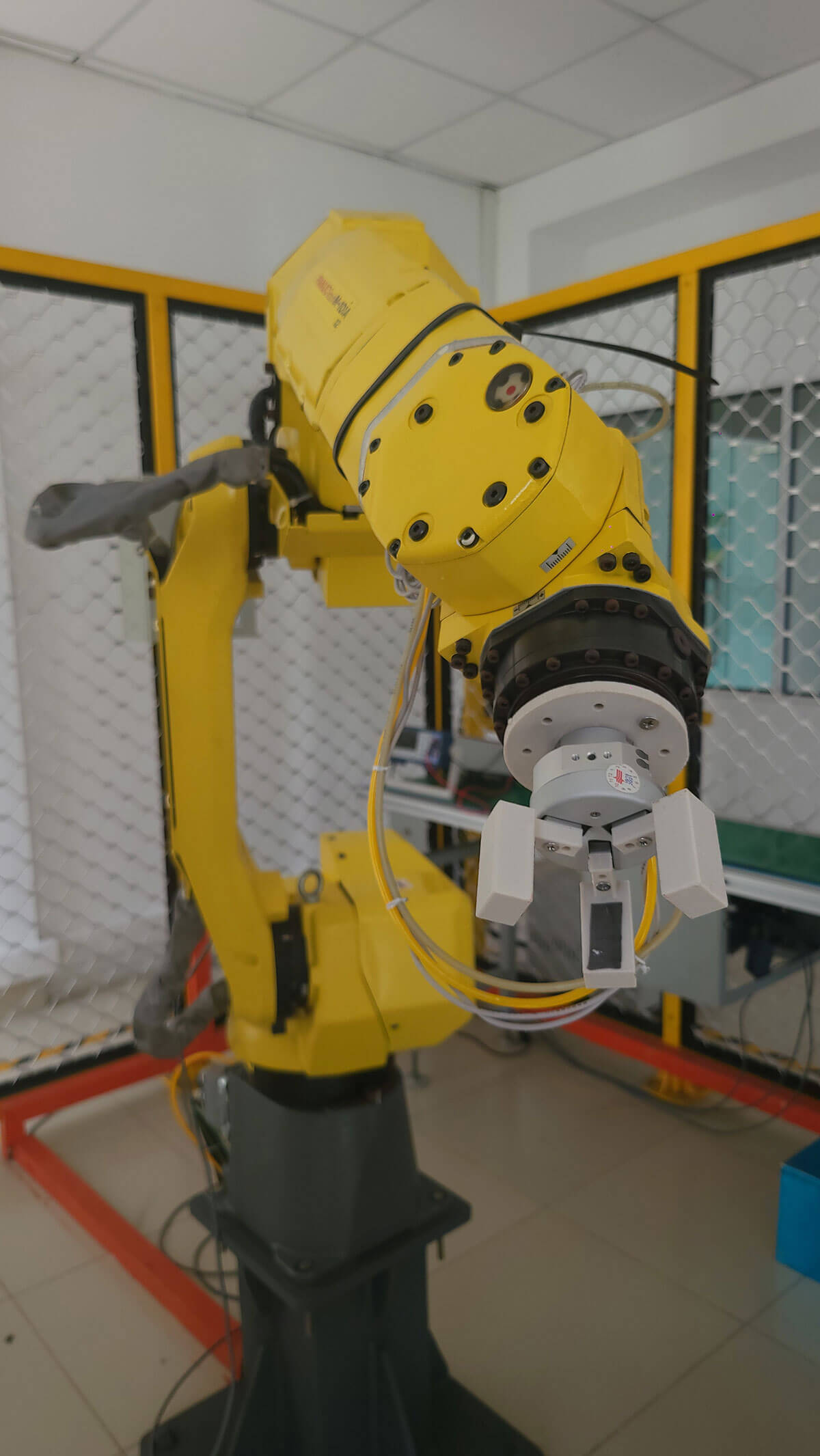

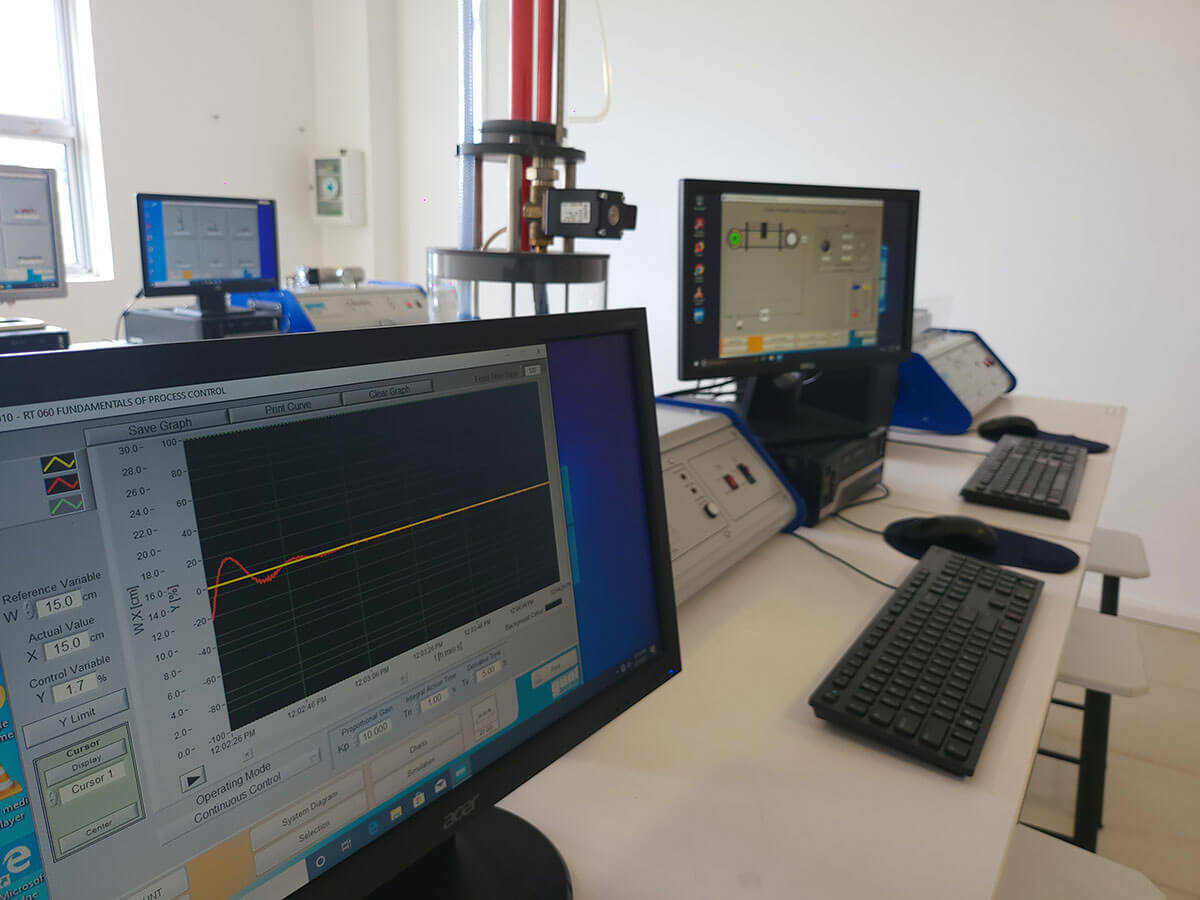

The department has a well-qualified staff consisting of professors, senior lectures, lecturers and instructors involved in the delivery of the programs. We also have visiting lectures who are experienced professionals to share perspectives from the industry. Laboratories are an indispensable part of the delivery of a Mechanical Engineering program. The department has a mechanical workshop and eight labs covering all major areas of mechanical engineering.

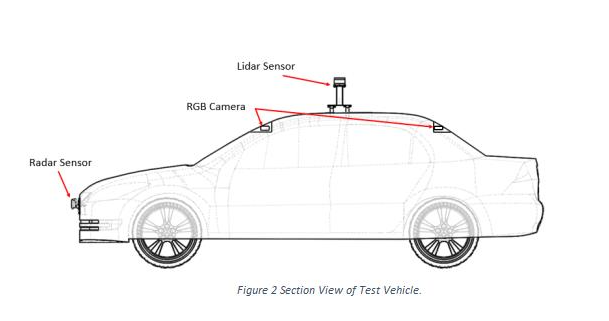

Over the years the department has built a broad network of partnerships with local and foreign industry and other organizations. The Bentley Computer Aided Engineering Unit established with Bentley Motors UK is the result of one such partnership. Our staff members are also involved in numerous research projects to find solutions to problems we face in modern times. We are also involved in internationally sponsored projects collaborating with other local and foreign universities.

The department always strive hard to maintain quality and produce graduates for industry and academia. We continue improve to on all aspects and our goal is to be a leader in years to come.